As the number of cell sites increase and their sizes decrease, engineers have options to consider for battery backup. Differing battery chemistries offer more choices and different performance levels. Selecting the right battery chemistry for each application is critical to ensure reliable, long lasting, and cost-effective power delivery.

The deployment of mmWave technology with 5G forces wireless operators to install many small cells, each at a reduced distance between the customer and the base-station antenna. Small cell sites are now located in buildings, on lamp posts, in neighborhoods, and along travel corridors. Each site must tap into available power, which can introduce an increased likelihood of power loss events.

What happens to the network each time we lose power? Of course, batteries engage and provide backup power for the location until grid power is restored. As the number of cell sites increases and the available footprint decreases, there are multiple options to consider for battery backup. Today’s battery chemistries offer more choices and different levels of performance than were available a short time ago. Selecting the best battery chemistry for each application is critical to ensure reliable, long lasting, and cost-effective power delivery. This article presents some of the considerations and trade-offs when selecting a battery for small cells.

Macro cell sites typically use lead-acid batteries for backup power, as well as fossil-fuel powered generators to provide power during a power loss event. Regulations typically stipulate that critical infrastructure must be operable for a certain amount of time during a power outage, typically 8 to 24 hours. The power requirements for macro cell sites vary depending on the site size, the number of collocated service providers, and the type of equipment. Additionally, the power load will vary throughout the day based on the number of active users of the site. All these factors affect the typical power requirements of a macro cell site.

Power requirements for small-cell sites are less than those for a macro cell because small cells typically serve a single operator, have a smaller coverage area, and tend to provide a specific type of coverage. There are some small cell site locations that provide critical coverage and need to provide service during a power outage. There are also small cell sites in locations prone to frequent power outages due to their location on the grid or in the community. In these cases, it’s important to consider the type of battery backup options. These sites are tucked in neighborhoods, commercial areas, in stadiums, and in higher numbers than their macro counterparts. Placing a battery at each small cell site or each cluster in stadiums makes much more sense than installing a fossil-fuel generator.

The two leading battery chemistries for small cell site backup power are valve-regulated lead acid (VRLA) and lithium ion. Each of chemistry has unique features that you should consider when selecting a backup power source. Factors include cost, weight, size, energy storage capacity, lifetime, operating temperature, and maintenance.

Lead-acid batteries were invented in 1860 and continue to be a leading energy storage product for many industries. There are multiple types of lead-acid batteries, but the most common for small site backup is the VRLA type. Lead-acid batteries built for telecom applications are the least expensive option in terms of cost per kWh installed at the beginning of life. This is due to the large, mature manufacturing base developed over the last 50 to 75 years. Operators have multiple vendors to choose from, all producing the same chemistry. Lead acid batteries are also highly recyclable, with up to 99% recyclability.

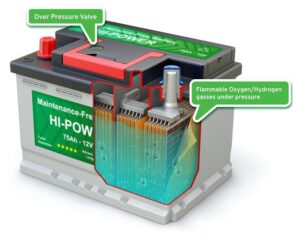

Figure 1. This 12 V VRLA battery used in telecom contains flammable materials and requires vertical orientation.

VRLA chemistry has some drawbacks. These batteries are built in 12 V increments and therefore require installing four pieces wired in series to power 48 V telecom equipment. These connections must be checked during regular maintenance intervals as they can become loose and cause a failure when discharged. VRLA batteries generate flammable hydrogen and oxygen as a normal part of operation. They’re used to pressurize the battery. In the case of a vent failure, battery failure, or overcharging, these gasses can escape into the room and therefore the rooms are regulated to provide adequate ventilation to prevent the risk of an explosion. Figure 1 shows a cutaway view of a VRLA battery.

Because there is a fluid (acid) in the battery and gas vents in the top, the mounting options for VRLA are limited to one orientation. Lead acid batteries are the heaviest of the available chemistries and require battery specific shelving, and floors to support the enormous weights of full battery banks. Additionally, if you discharge a VRLA battery less than 50%, permanent damage occurs to the lead plates and will significantly reduce the lifetime of the batteries. This requires operators to either replace their batteries earlier than anticipated or suffer a system shutdown during a power failure event due to failing batteries.

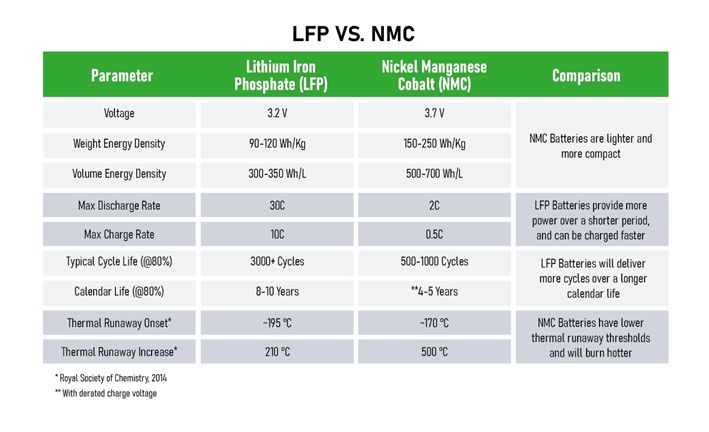

Introduced in the 1970s, lithium-ion batteries recent improvements in chemistry, cost, and manufacturing have made them attractive alternatives to lead-acid batteries for the telecom industry. There are multiple lithium-ion battery chemistries, but two dominate in the telecom industry: lithium nickel manganese cobalt (NMC) and lithium iron phosphate (LFP). These chemistries are quite similar, but have a few differences illustrated in Table 1. These chemistries are manufactured in 48 V rack mountable form factors and can be wired in parallel to provide the required backup capacity. There are special considerations when wiring Li-Ion batteries in parallel, depending on the technology integrated directly into the battery by each manufacturer. Li-Ion batteries of different SOC, capacity, and age should not be wired in parallel unless the manufacturer integrates special balance circuitry. Mixing and matching Li-Ion batteries without proper balance circuitry will lead to accelerated wear at the least, and unpredicted down time at the worst. (Table 1)

Lithium-ion batteries are more energy dense, weigh less, and take up less space than lead acid. Additionally, lithium-ion batteries can be cycled to 100% depth of discharge to approximately 3500 cycles before they degrade to a point where they should be considered for replacement. This feature alone allows lithium batteries to be designed into systems for 10 or more years without replacement. This allows for more backup time to be provided in a smaller space. This is advantageous to small cell installations where space is at a premium.

Lithium-ion batteries are also completely sealed; you can mount them in any orientation. This allows for installers to squeeze batteries into tight locations, mount the battery sideways, or even upside down. Small cell sites with equipment boxes located on poles, in closets, or tucked away in a utility right of way are usually limited in space and need to be as small as possible.

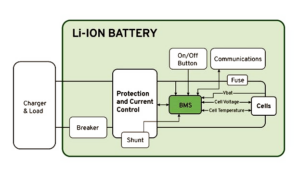

Figure 2. A telecom Li-ion battery contains a battery-management system (BMS), circuit protection, and communicates its health to the host.

One of the biggest benefits to lithium-ion batteries is the built in Battery Management System (BMS). Every lithium-ion battery must have a BMS that monitors cell voltages, battery currents and temperatures and will protect the battery from abuse. This provides a built-in safety measure, prolonging the life of the battery by ensuring the battery operates in optimal conditions. There are many additional features that BMS’s offer such as state of charge, state of health, cycle count, fault reporting, digital communications (i.e., RS485, Modbus), and integration with site controllers. These features (Figure 2) enable remote battery management, eliminating routine maintenance trips to remote sites and significantly reducing maintenance costs. Now operators can send a technician to check on a set of batteries after the batteries proactively send a request for maintenance through the cloud.

As the wireless industry transitions to 5G and small cell sites, the power requirements for each site have been increasing. Each site is becoming more unique in requirements as we put more radios in more places. Operators must be cautious with their power supply designs and deployments. There are a few options when it comes to powering backup systems, including fossil fuel generators, lead acid, and lithium-ion batteries. Each solution has its own benefits, and each small cell site will require evaluation and integration to ensure that critical communications are available when they are needed most.

Related articles:

-

- Li-ion batteries, Part 1: Building massless batteries

- Li-ion batteries, Part 2: Cathodes

- Li-ion batteries, Part 3: Anodes

- Li-ion batteries, Part 4: Separators

- Li-ion batteries, Part 5: Electrolytes

- Battery Management Systems: Effective ways to measure state-of-charge and state-of-health

- R&D winner of the day: a new Cobalt-Free Li-ion Battery Cathode Material