A MEMs device generates enough power to run a typical GPS IC

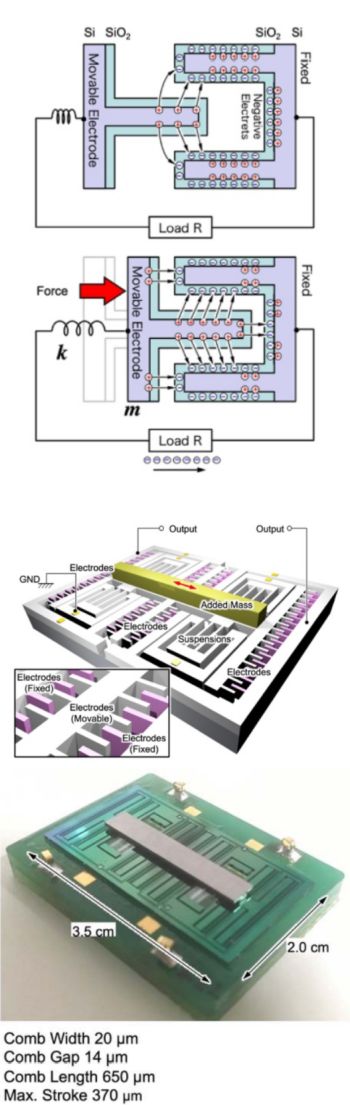

Researchers at the University of Tokyo have come up with microelectromechanical systems (MEMs) vibrational energy harvester that yields a maximum power of more than 1.2 mW from environmental vibrations of 0.65 G (1 G = 9.8 m/sec2) at 158 Hz. The device works by means of electrostatic induction developed using a built-in potential produced by permanent electrical charges or so-called “electrets.”

An electret is a dielectric material that has a quasi-permanent electric charge or dipole polarization. An electret generates internal and external electric fields and is the electrostatic equivalent of a permanent magnet. In a presentation to be given at the upcoming IEDM conference(MEMS Vibrational Energy Harvester for IoT Wireless Sensors, H. Toshiyoshi, Univ. Tokyo), the researchers will describe a harvester architecture consisting of an electrode that moves in and out of the electret field in the presence of vibrations. The researchers used silicon oxide as the electret material. Silicon oxide is known to be negatively charged when it contains potassium ions driven out by electrostatic force. Researchers used the silicon oxide on the surface of MEMS electrodes as an electret skin to induce electrostatic displacement current. The electrodes are arranged in a symmetric structure to cancel constraint forces in the opposite directions.

The energy harvester chip measures 3.5×2.0 cm. Researchers added a tungsten mass of 2.5 gm to help harvest the kinetic energy from the environmental vibrations. The device is fabricated on a silicon-on-insulator (SOI) wafer containing a thick active layer of silicon on top of a 1-μm-thick buried oxide (BOX) layer and a 500-μm-thick handle wafer. Both the top and the bottom sides of the wafer are processed by deep reactive ion etching (DRIE). After the sacrificial removal of the BOX, the entire silicon surface is thermally oxidized at 980°C to form a silicon-oxide skin, which is then turned into an electret via an aqueous solution of potassium hydrogen oxide (KOH) to form an impurity-rich silicon oxide.

After the oxidation, the silicon electrodes are electrically biased at 200~500 Vdc on a hot plate, driving the impurity K+ ions out of the oxide on the anode side, leaving SiO– voids behind as a source of negatively charged electrets. Accelerated reliability tests at elevated temperatures indicate the electret is expected to have a lifetime (defined by −1 dB decay) of more than 400 years at 25°C; it drops to 8 years at 65°C, equivalent to the typical behavior of electrolytic capacitors.

The 66th annual edition of the IEEE International Electron Devices Meeting (IEDM), the world’s premier forum for the presentation of applied research in transistors and related devices, will take place virtually this year. The conference will now run from Saturday through Friday, December 12-18, 2020, and will offer a mix of live-streamed events and on-demand pre-recorded presentations, with a schedule of live Q&A sessions. The expanded schedule is intended to give global attendees enough time to review the more than 220 papers in the IEDM technical program, plus the tutorials and short courses, and to participate in the live-streamed events, such as the plenary presentations, panel discussion and career session.

This year’s theme is “Innovative Devices for a Better Future,” which reflects the fact that, at a time of great global uncertainty, electronics technology is being used much more broadly than ever before to address the world’s most pressing challenges.

“This year’s format may be different, but what hasn’t changed at all is that IEDM will once again offer an outstanding technical program that showcases important breakthroughs in key semiconductor and related technologies, which are essential for the progress of modern society,” said Dina Triyoso, IEDM 2020 Publicity Chair and Technologist at TEL Technology Center, America, LLC. “I’m very proud of the fact that, despite the laboratory restrictions and all of the other challenges imposed on us by the pandemic, our community has persevered and driven the state-of-the-art of electronics technology forward yet again.”

“Although a virtual experience doesn’t give us the ability to see our colleagues in person, it does provide unique opportunities which we have tried to maximize,” said Meng-Fan (Marvin) Chang, IEDM 2020 Publicity Vice Chair, IEEE Fellow, Distinguished Professor of Electrical Engineering at National Tsing Hua University and Director of Corporate Research at TSMC. “For example, if IEDM were a physical event this year, nine technical sessions would run in parallel. An attendee likely would find it difficult to attend all talks of interest. But with recorded presentations available on-demand a week ahead of time, that roadblock is eliminated.”

Leave a Reply