In part 1, we presented an overview of the product life cycle (PLC) and product development cycle (PDC), as well as the difference between the two. Part 2 explained in detail the 12 steps of the product life cycle (PDC). In this final part, we offer some practical suggestions on PDC implementation.

The secret to successful implementation of PDC

Most organizations have a formal procedure for most activities, but it is an informal procedure that gets things done. This includes relationships, exchanging favors, and other personal, yet legal, dealings. Why? It is because the formal procedure cannot cover 100% of the varied and unforeseen scenarios. To be able to implement the PDCM process successfully, the following ideas are recommended.

Foster an environment of innovation

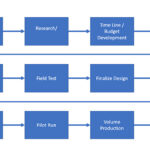

Power struggles within an organization are unavoidable as long as there are limited resources or rewards; different teams have to fight for those resources. However, the environment does not have to be one of conflict. Take the example of a wise manager: One time, during a design review meeting, it was pointed out that there was a design flaw. Everyone was uneasy and ready to point out it was the fault of someone else. The manager calmly asked for suggestions on solutions. Slowly, people started to share ideas. No attention was paid to “who was at fault.” After a few such meetings, everyone caught on and was eagerly contributing to the best ways to solve the problems. It is crucial to help the team focus on solutions and not on blaming others. Figure 1.

Empower the team

One time a new director of marketing asked the boss, the VP of marketing, how to solve a problem. The VP responded, “You are the director; you should know the answer.” The director was demoralized. On the contrary, one wise manager told his team members, “My job is to provide you with the tools and resources you need to get your job done.” The team was very motivated to try new things and get things done, knowing the boss was behind them.

Always have a contingency plan

Plan A does not work all the time, so it would be helpful to have a back-up plan in place, whether it is a formal or informal plan. When things don’t work out, the team does not need to panic and make more mistakes. Plan B may not be as good as plan A, but it is a plan.

Conclusion

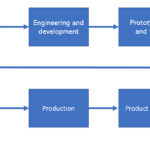

Developing a Product Development Cycle Management process will avoid a one-time wonder and maximize the probability of having on-going new products. Before a product is introduced, there is a 12-step procedure to be carried out. These steps span production definition to development to production. It is important to keep in touch with the market and customers to avoid inventing products in a vacuum.

Finally, the formal process aside, to have real success in practice requires fostering an environment of innovation, empowering the teams, and always having a contingency plan in place. While they are tools such as product management and even artificial intelligence to aid the development of product plan, providing leadership to energize the team is the key. After all, it is a people management business.

Leave a Reply