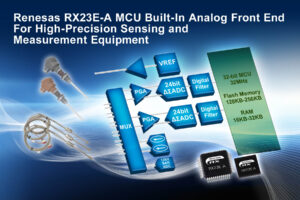

Renesas Electronics Corporation introduced the RX23E-A Group 32-bit RX microcontrollers, combining high-precision analog front end (AFE) and an MCU on a single chip. Designed for manufacturing and test and measurement equipment applications that require high-precision measurements of analog signals for temperature, pressure, weight, and flow, the RX23E-A MCUs are the first Renesas solutions to enable such signals to be measured with better than 0.1% precision without calibration.

Renesas Electronics Corporation introduced the RX23E-A Group 32-bit RX microcontrollers, combining high-precision analog front end (AFE) and an MCU on a single chip. Designed for manufacturing and test and measurement equipment applications that require high-precision measurements of analog signals for temperature, pressure, weight, and flow, the RX23E-A MCUs are the first Renesas solutions to enable such signals to be measured with better than 0.1% precision without calibration.

The new MCUs achieve AFE precision at the highest class in the industry (offset drift: 10 nV/°C, gain drift: 1 ppm/°C, and RMS noise: 30 nV rms), a level that could previously only be achieved by combining dedicated A/D converter circuits with high-precision operational amplifier ICs. By integrating this high-precision AFE IP (intellectual property) on a single chip using the same fabrication process technology, Renesas has made it possible to implement high-precision sensor measurement, computation, control, and communications on a single chip. This allows system manufacturers to reduce the number of required components, save space, and simplify system design in a wide range of equipment requiring high-precision measurements, such as sensing, temperature controllers, recording, weighing, and force sensing. It also accelerates endpoint intelligence by enabling distributed processing with MCUs.

With big data-driven quality and productivity improvements, the pressure is on for factories and manufacturing sites to measure a wide variety of sensor data accurately and reliably. Since users require stability when measuring small signals at high precision over a wide environmental temperature range, it is important to reduce noise characteristics and temperature drift characteristics to low levels. To address these needs, Renesas has developed a high-precision AFE and integrated it into an RX MCU with an extensive track record with industrial applications.

The RX23E-A MCUs are based on the RXv2 core, which features operating speeds of 32 MHz, a digital signal processor (DSP), and superlative floating point unit (FPU) calculations. This allows the implementation of adaptive control using temperature data and inverse matrix calculations using 6-axis distortion data. For example, robot arm force sensors require the measurement and calculation of the 6-axis distortion in a small space. The RX23E-A MCUs make it possible to measure the 6-axis distortion data and perform the inverse matrix calculations with a single chip.

Samples of the RX23E-A Group of MCUs are available now with mass production planned for December 2019.

Leave a Reply