A servo motor, used for position feedback of angular rotation, applies pulse width modulation (PWM) signals for precise control over motion. Industrial design engineers can change the rotation angle and direction of the motor by varying the width of the PWM signal, and here, the role of MCU, which generates the PWM signal, inevitably becomes crucial.

A microcontroller generates a PWM signal using a timer, and subsequent configurations can be modified to rotate the arm of a servo, a specific class of motor often used to create closed-loop control systems in industrial robots, CNC machinery, and automated manufacturing.

A servo motor employs position feedback to control its motion and final position, and that demands a relatively sophisticated microcontroller. On the other hand, general-purpose processors can be problematic because of their use of cache memory; run time varies greatly in the cache memory, and that can impact the servo motor control.

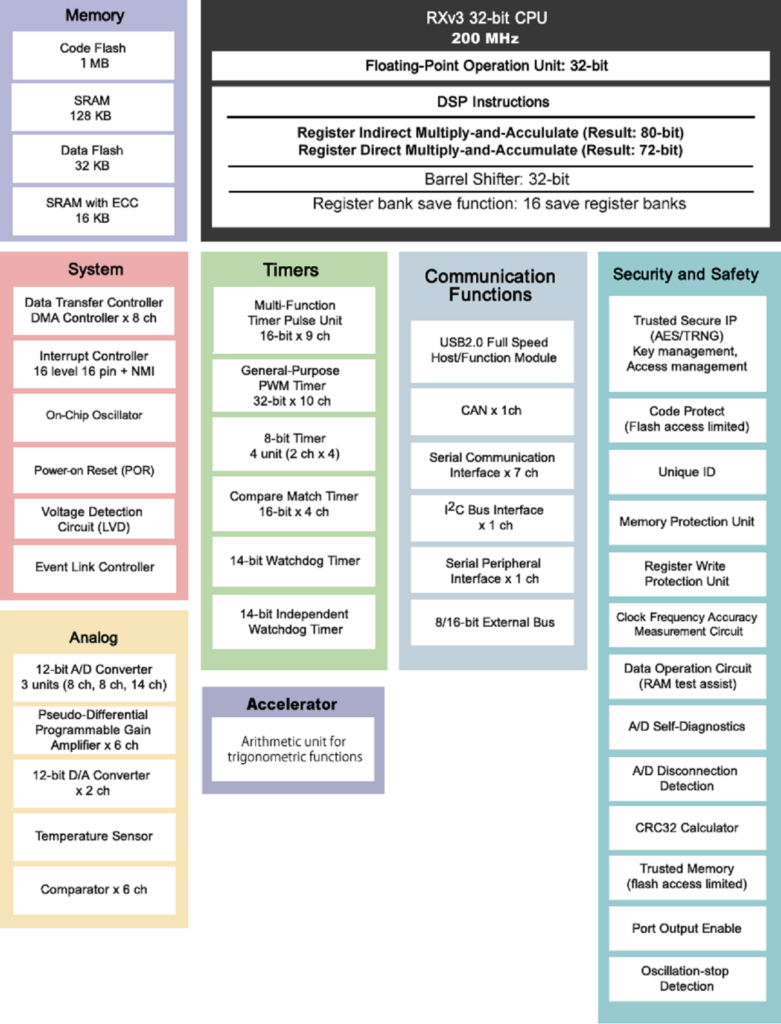

So, what distinguishes servo control MCUs from other MCUs? What are the specific traits that servo control MCUs feature as compared to off-the-shelf MCUs? For a start, these MCUs are optimized for industrial robotics and motor control with built-in IP to facilitate advanced control for servo motors.

Anatomy of servo control MCUs

The dedicated hardware accelerators inside MCUs facilitate high-speed position calculations required for implementing servo control in industrial robots and other factory automation applications. The current control loop calculations performed in time frames as small as 1.5 µs also allow developers to create low-cost servo systems.

It’s worth mentioning that servo control calculations can also be performed in software, but that creates an excessive compute overhead for the main MCU or MPU. At the same time, however, the fully hardware-based calculations can be a hindrance in implementing unique control operations.

That calls for MCUs that come with built-in IPs that bolster the calculation speed and precision of interrupt handling for specific motor control applications. The motor control MCUs with dedicated hardware accelerator IP can perform the complex, high-speed computations required for servo control in robots and other industrial automation equipment.

While this article has attempted to explain how servo control MCUs can improve manufacturing efficiencies in industrial environments, it’s worth mentioning what’s new and latest in this realm. First, servo control MCUs are incorporating hardware cryptography to ensure security and reliability in industrial designs.

Then a new breed of AI algorithms is enabling developers to employ mechanisms such as motor control failure detection with a single MCU. In short, servo control MCUs are going through a rapid make-over to address the new industrial design requirements in the rapidly emerging Internet of Things (IoT) era.

Leave a Reply