ROHM Group Company LAPIS Semiconductor has announced the development of the ML620130 family of 16bit low power MCUs, optimized for compact industrial equipment requiring battery drive in noisy environments, featuring superior processing capability with low power consumption.

ROHM Group Company LAPIS Semiconductor has announced the development of the ML620130 family of 16bit low power MCUs, optimized for compact industrial equipment requiring battery drive in noisy environments, featuring superior processing capability with low power consumption.

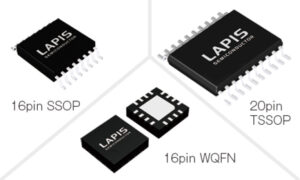

In addition to clearing the ±30kV noise measurement limit, operating voltage has been successfully reduced to 1.6V. Optimizing the operating voltage to an integral multiple of standard nickel metal hydride batteries (0.8V x 2=1.6V) ensures efficient use without wasting battery charge. This contributes to decreased battery consumption, prolonging battery life in portables and battery-equipped industrial equipment. The ML620130 family consists of 9 models offered in a variety of memory capacities, pin counts, and other characteristics that make it possible for users to select the ideal solution to fit set needs.

In recent years, the continued miniaturization of sensors, batteries, and power supplies has increased the demand for compact, low-cost modules (embedded substrates) that support a variety of applications and operating conditions. When considering different situations and usage methods there is a need to ensure stable operation under harsh environments (i.e. excessive noise, heat generation) while at the same time requiring improved performance such as greater communication diversification and generalization.

To provide increased miniaturization and lower costs, many applications are opting to eliminate noise and/or thermal countermeasures. However, this makes it difficult to balance the conflicting demands for increased environmental resistance while maintaining safety utilizing fewer external parts. In addition, reducing the size of the battery mounted in the module while also increasing battery life requires that the power consumption (voltage and current) be optimized for each application.

To meet these disparate needs, LAPIS Semiconductor has expanded its lineup of market-proven 16bit low power microcontrollers to include the ML620130 family of ‘tough‘ MCUs that incorporate multiple functions optimized for battery drive operation.

Key Features

1. Optimized for ultra-low-voltage rechargeable nickel metal hydride batteries

The minimum operating voltage has been decreased, from the conventional 1.8V to 1.6V. This extends the supply voltage detection range down to 1.63V (typ.) – very close to the voltage of 2 nickel metal hydride batteries (0.8Vx2=1.6V) – reducing the number of charge cycles and memory effects while prolonging battery life.

2. Improves basic performance and reduces current consumption

16MHz CPU and 32MHz (PWM) peripheral clock operations increase performance by 2-fold over LAPIS standard lineup of ‘tough’ MCUs, while operating current is reduced by more than 25%.

3. Class-leading high-accuracy on-chip oscillator eliminates the need for an external oscillator

A high-accuracy on-chip RC-type oscillator is built in (±1%@-20°C to +85°C, ±1.5%@-40°C to +105°C). UART communication (asynchronous method), which has been widely adopted for a variety of uses as an interface for external equipment, is enabled throughout the entire temperature range without an external oscillator, reducing peripheral component costs. In addition, both full-duplex (x1ch) and half-duplex (x2ch) modes are allowed, and in the event that bidirectional communication is not required at the same time the 2 receiving terminals and 2 transmission terminals can be flexibly assigned, making it possible to mount on smaller boards.

4. Superior noise immunity

High noise immunity inherited from LAPIS Semiconductor’s conventional lineup of low-power MCUs makes it possible to clear the ±30kV Level 4 measurement limit (air discharge: ±15kV) of the IEC61000-4-2 standard*1. In addition, implementing circuit enhancements related to power lines and noise intrusion pathways resulted in a 30% improvement in noise resistance (verified via indirect discharge using LAPIS Semiconductor’s reference board under specific conditions).

LAPIS Semiconductor

www.lapis-semi.com

Leave a Reply