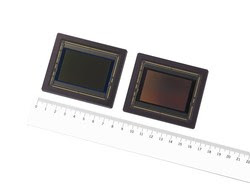

Sony Corporation announced today the upcoming release of a large format 56.73mmdiagonal CMOS image sensor “IMX661” for industrial equipment with a global shutter function and the industry’s highest*1 effective pixel count of 127.68 megapixels.*2

This product features an increased pixel count that yields an optical size nearly 10 times larger than the common 1.1-type image sensor corresponded to the C mount*3 for industrial equipment. It also features Sony’s original global shutter pixel technology “Pregius”, which enables the capture of motion distortion-free images. Furthermore, Sony’s original device configuration and interface technology employed enables high-speed image readout at a data rate nearly four times faster*4 than conventional products.

Sony expects that the new sensor, when used in industrial equipment cameras for a wide variety of applications, will help to solve a variety of complex challenges, thereby contributing to the development of the industry.

Needs for automation, labor-saving, and other benefits of digital transformation continue to grow in recent years in various fields of industrial equipment. This has accelerated the adoption of cameras for a wide variety of applications, driving demand for CMOS image sensors with higher imaging performance.

The new product couples Sony’s Pregius technology with the 3.6-type (56.73mm diagonal) large optical size, delivering an increased pixel count and motion distortion-free imaging. The original device configuration, which employs a chip-on-wafer process, together with Sony’s original interface technology, enables high-speed readout nearly four times faster than conventional products*4 in full-pixel readout mode. This design delivers highly efficient imaging that captures a wide viewing angle with no motion distortion in a single imaging operation. It also improves recognition precision thanks to high-resolution imaging and delivers a high level of processing performance. It can contribute to solutions for a variety of industrial equipment applications, for example, inspection processes for the production of displays and electronic substrates, wide-area monitoring, and aerial photography, where its improved precision and the quicker readout will help meet the need for a high level of productivity.

Leave a Reply