Apple recently came out with the Series 3 version of its watch. We can get an idea of how the Series 3 goes together from a teardown analysis of Apple’s earlier Sport model.

The Sport model we analyzed has an aluminum case but the watch is also available in stainless steel. It measures about 39 × 33 mm and is about 10.5 mm high. The glass display has a density of 272 by 340-pixels. You access the watch electronics by prying off the display using a razor blade. Beneath the glass display, we found a gasket apparently there to provide some waterproofing.

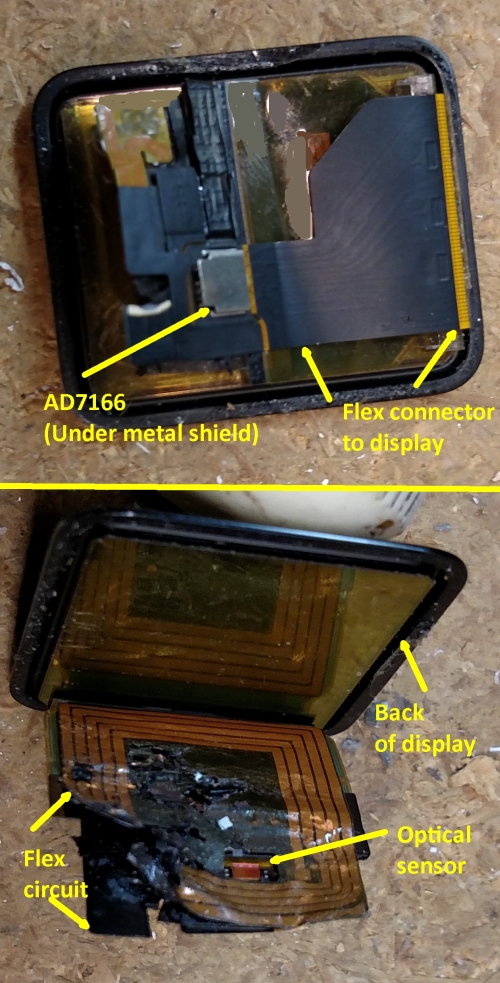

The watch display connects to the rest of the electronics through a relatively complicated flex circuit that includes a serpentine conductor pattern as you might find serving as a pick-up coil for a wireless charging scheme. Also on the flex circuit is a chip from Analog Devices that seems to be a touchscreen controller. We say, “seems to be” because the part number we found on the chip, AD7166, isn’t a standard part number. We can only say that judging by its position on the flex circuit and according to other analyses we’ve seen, it seems to be doing touch control.

Next to the Analog Devices chip is what seems to be an optical sensor pointed at the display. Apple was granted a patent on this idea a couple years ago. Basically, the sensor gauges how bright to make the display. What’s interesting is that the sensor sits behind the display panel, instead of being mounted on the surface of the display as in most smartphones and tablets.

With the display and flex circuit detached, the 3.8-V, 205 mA-hr. lithium-polymer battery comes into view, along with several components attached to the case with super tiny screws. We counted 16 screws used in the watch. Specifically, screws hold the speaker and taptic engine in place. Ditto for an antenna assembly that sits on one side of the case. Another two screws hold a mechanical button to the side of the watch case. Two more hold a metal door that covers a hidden diagnostic port.

To complicate things a bit, the screws have a tripoint head that is not a standard type. We had to special order screwdriver heads to fit them. Just as a general comment, screws are a relatively high-cost way of attaching components. It’s unusual to see this many of them used in a mass market consumer product. And this liberal use of screws probably didn’t help Apple keep the cost of its watch down.

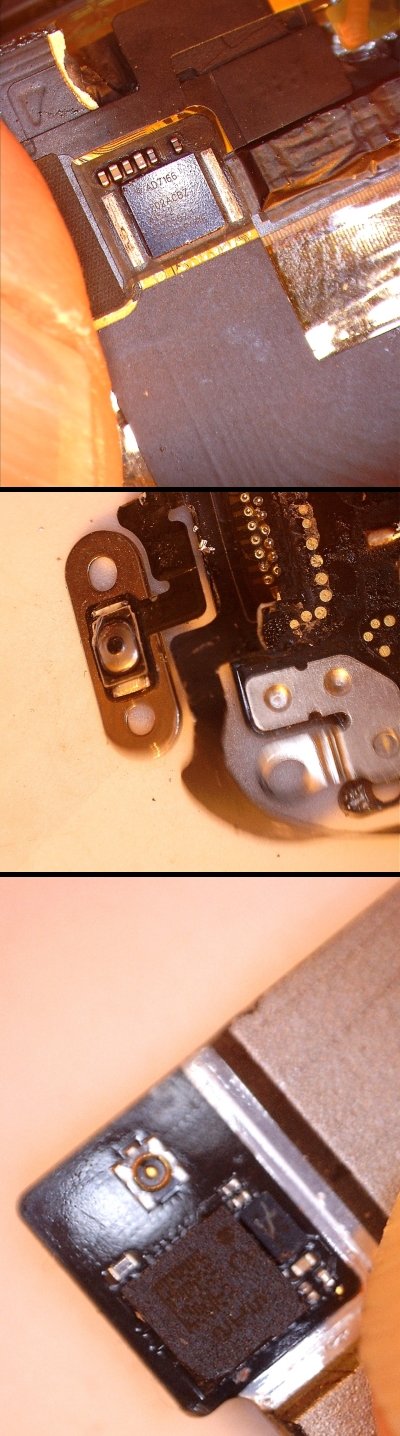

One of the things fastened by screws is a metal bracket around an encoder wheel for the adjustment knob on the case. This bracket was a bit puzzling. There doesn’t seem to be an obvious reason for it. In any event, the knob works a little like the front panel knobs found on modern test instruments: In older generations of instruments, these knobs would be on potentiometers. Today, instrument knobs attach to a position encoder that provides a readout of the knob position.

Similarly, the adjustment knob in the Apple Sport watch uses an encoder this way. Judging by the mirrored multifaceted surface on the encoder wheel, the encoder is probably an optical type that reflects LED light onto an optical sensor as the encoder wheel turns as a way to register changes in the position of the adjustment knob. And if you look carefully beneath the encoder, you see what may be a light sensor and LED that produce the encoder readout.

Near the encoder wheel sits what Apple calls its taptic engine which provides tactile sensations in the form of vibrations to the watch wearer. Taptic engines can also be found in iPhones, iPads, and MacBook laptops. The taptic engine is basically a rod that is spring loaded at each end and vibrates back and forth in a few distinct ways to alert the wearer about different events.

Butted up next to the taptic engine is a speaker. The two are probably packaged together because when combined with subtle audio cues from the specially engineered speaker driver, the Taptic Engine is designed to make a special kind of motion.

There are several other components attached to the inside edge of the watch case. One of them is an antenna assembly that is on flex circuit-type material and probably handles the Wi-Fi and Bluetooth transceivers. The mechanical button is also positioned on the side of the case, along with the diagnostic port.

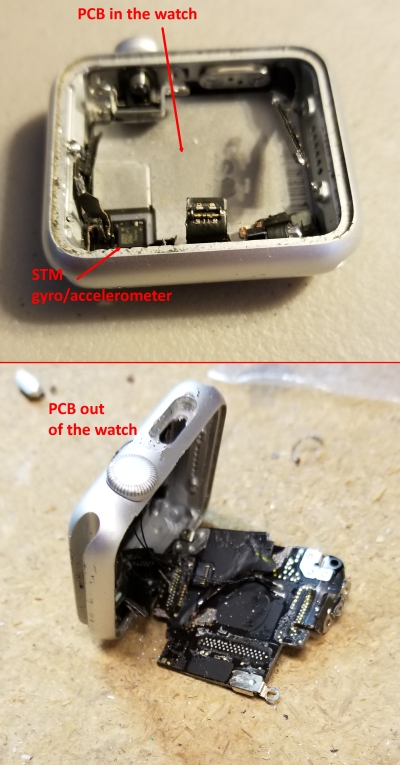

Most of the electronics on the Apple watch sits within a 26×28-mm motherboard. We say it sits within the motherboard because the whole board and all the components are over-molded with a special packaging compound that includes silica or alumina spheres suspended in a resin. And this over molding makes it impossible to see all but one of the board components. Nor can the over-molding be removed with chemicals you might ordinarily use to remove conventional IC packaging to get a better look at the chip dies. That’s too bad because the board reportedly contains more than 30 components and includes the Apple application processor that runs the whole watch.

So, we couldn’t actually look at the individual chips on the board except for one which sits outside the over-molding material. That chip is from STM and holds a 3D digital gyroscope and accelerometer.

Given the difficulty of getting at the individual board components, for this teardown, we had to be content with removing the board, which wasn’t easy, and eyeballing what we found underneath it. Removing the board gives a view of the electronics used for wireless charging and the heart rate monitor. There is one chip visible on the back substrate. It is a precision low-noise op amp from Texas Instruments that we might surmise handles the ultra-low signals that are involved in sensing the wearer’s heartbeat.

Removing the board gives a view of the electronics used for wireless charging and the heart rate monitor. There is one chip visible on the back substrate. It is a precision low-noise op amp from Texas Instruments that we might surmise handles the ultra-low signals that are involved in sensing the wearer’s heartbeat.

The back of the substrate contains what appear to be light sensors and LEDs used in sensing the wearer’s heartbeat. The Apple watch uses the same technique as the FitBit for sensing heartbeats. The measurement technique is called pulse oximetry. (Apple calls it photoplethysmography but it is the same thing as pulse oximetry.) The technique takes advantage of the fact that oxygenated and deoxygenated hemoglobin have different optical properties. With every heartbeat, there is a spike in arterial oxygenated blood, which is detected as a change in the absorbance or reflectance of green LED light. So the optical sensors measure the amount of LED light reflecting from the blood under the wearer’s skin. The reflectance is a bit different during a heartbeat, and the sensor will detect this periodic signal from which the heart rate is extracted.

Finally, with the lower substrate removed, we see the back of the aluminum watch case and the optics involved in the heart rate detection. Also, there is a magnet that holds the watch to its wireless charging cradle.

Great article, Thanks for writing.