A group of researchers at the University of Washington have figured out a way to make 3D-printed objects emit WiFi signals containing status information, all without using electrical power.

Researchers implemented the backscattering idea by 3D-printing a WiFi antenna, then connecting and disconnecting it as a way to reflect and not-reflect the WiFi signal to form a coded pattern. Then a receiver — they used a MAX2829 802.11a/b/g transceiver — decodes the backscatter information from the amplitude variations in the received Wi-Fi signal across packets.

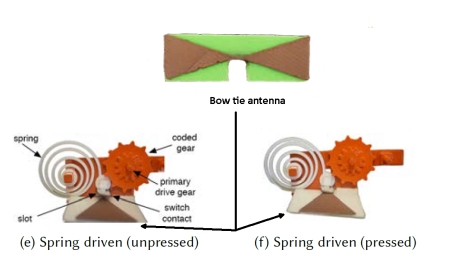

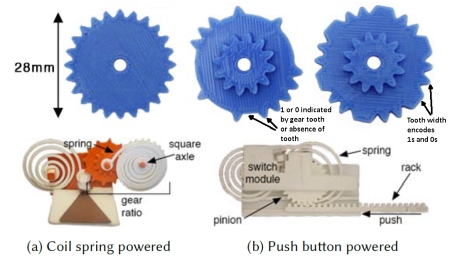

To generate a digital code without using external power, the group devised a spring-actuated switch actuated by a coded gear. When a gear tooth pressed down on the switch, it would make a connection between the two halves of the bow tie antenna. They tried two kinds of coding schemes: one where the presence of a gear tooth indicated a 1 bit and the absence of a tooth indicated a 0 bit, and a second where a gear encoded 1s and 0s by doubling the tooth width in a manner analogous to Morse code.

Researchers tried several kinds of springs but got good results using a planar coil spring orthogonal to the contact surface. A slot guides the contact to ensure it stays parallel to the contact surface. The coded gear couples to a 3D-printed, tightly coiled planar spring where the outer edge of the spring is held at a fixed point, and the center couples to a gear using a square axle.

The spring gets wound up to “charge” the device, then applies torque to the square axle and therefore to the connected gear as it unwinds. The gear to which the coil spring attaches, in turn, actuates a circular gear with the encoded bits. By controlling the ratio between the size of the primary and circular gears, researchers control the speed at which the switch toggles between the two states.

The researchers described their work at the recent ACM Siggraph Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia.

What is absolutely missing in this paper is, how the backscatter information actually was extracted from the MAX2829 chip. The diagrams in the paper give no information about time scale or frequency ranges, also the text does not and leaves everything open to guesses.

Does one need to assume that sophisticated and expensive laboratory equipment, capable of performing signal analysis in the GHz range is required, and that the task is not able to be accomplished with hardware that is equivalent to the low-end 3D printing equipment that is advertised to make the backscatter gadgets so attractive to the outside world (namely , i.e. by using small scale, affordable and easy to program micro controllers like Arduino or ESP32?)

In effect, the referenced commercial WiFI routers need to modified, be it on the hardware level or by using additional software. In my humble opinion, this missing information is a crucial requirement for a scientific publication.

As a scientific reviewer, I would not have accepted the paper in this form for publication.

I think the key here is this passage from the Siggraph paper: “In our case, the backscatter signal is a narrowband transmission embedded on top of the ambient Wi-Fi signals, since the printed Wi-Fi objects send data at a low data rate. The Wi-Fi receiver can extract this information by tracking the amplitude of Wi-Fi signals across multiple packets. Specifically, we normalize the received Wi-Fi signals across packets on a scale of +1 to -1 and apply a 10th order 100 Hz low pass filter. This filters out the high frequency information in the Wi-Fi signal leaving the backscatter data. Our filter parameters are chosen to minimize noise at bitrates up to 45bps, which is a standard technique in communications. Additionally, our filter bandwidth minimizes the amount of high frequency noise. The resultant data can then be processed for sensing by mapping the sensor value to the rate at which bits are backscattered by the sensor….”

If I understand this correctly, they are just applying some kind of envelope detector to the received reflected WiFi signal. No modification of the WiFi router would be necessary.

I know this is an old comment, but I figure it might be worth asking:

Does this setup not require a dedicated transmitter? The way I read the paper, I was think there was a transmitter that sent a constant known signal, and the buttons and devices overlayed their backscatter data on top of that. The difference in the known signal and what would be received by a client would be the end signal.

If this isn’t the case, and there isn’t a known given signal, how can they distinguish between noise/interference/arbitrary wifi and backscatter data?

This is Amplitude Modulation. They use a WiFi receiver and monitor the received signal strength. They then calculate the variations of that number over time in reference to the “baseline” level. They filter those variations so that only the signal variation at the rate they want (45 bits/sec) is left. Their WiFi signal is up to 16M away but the range at which they can detect the variations they induce is really low 16 cm.

With such a low detection distance, I am not sure of the real benefit, unless they can find a detector that required no work, Otherwise they have to build and program the detector.

They could just as well have used a mirror to modulate light reflection from the printed device, and a longer range than 16 cm I would expect.

But it is a fun project anyway.