Single-Pair Ethernet (SPE) isolation inductors and transformers are available in several configurations. They are used in applications where simple capacitive isolation is not sufficient. There are two types of SPE isolation transformers: simple chip transformer designs and so-called case transformers that combine isolation functions with common mode rejection.

This article examines the applications for SPE isolation inductors, the technicalities separating isolation inductors from transformers, and the emergence of industrial SPE, which drives the need for transformer isolation.

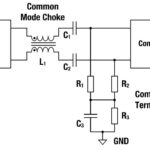

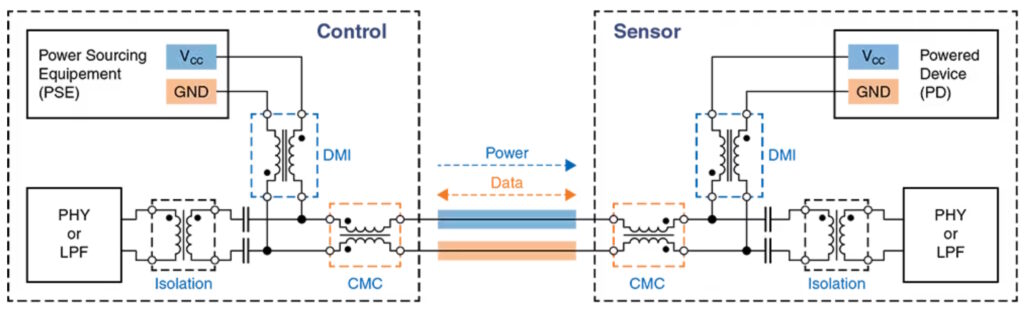

SPE isolation inductors are needed in one of the three SPE implementations. The two implementations without an isolation inductor are simple data transfer and non-isolated power over the data line (PoDL). The third includes safety-critical applications where galvanic isolation is required. For these environments, an isolating transformer or coupled inductor is used in addition to the common mode inductor (CMI), sometimes referred to as the common mode choke (CMC), and the differential mode inductor (DMI) to prevent unwanted currents from flowing between the two devices (Figure 1).

The difference between an isolation transformer and a coupled inductor is largely semantic and based on the application. Isolation transformers are associated with power applications, while coupled inductors are often associated with signal applications.

SPE was initially developed for automotive applications. In 12 Vdc-powered automotive environments, capacitive isolation is often all that’s needed. As SPE has been extended into industrial Internet of Things (IIoT) applications and machine and building automation, higher isolation levels are required.

When capacitors aren’t enough

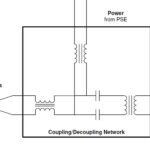

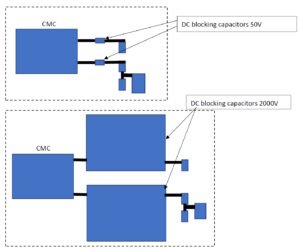

Capacitors with 50 to 100 V isolation that work in automotive applications don’t fit in the industrial applications for SPE. The IEEE 802.3cg standard, which is the basis for industrial SPE, requires insulation according to IEC 62368-1 requirements. The IEC standard calls for withstanding 1,500 Vac (2,250 Vdc) for 60 seconds. That requires the use of blocking capacitors rated for 2,000 V isolation. Current capacitor technology is not suited for such high voltages. For example, standard multi-layer ceramic capacitors (MLCCs) made with X7R dielectric and rated for 0.1μF in a 2225 size are only rated for 1,500 V. Capacitors rated for 2,000 V as required by IEC 62368-1 would be too large to be practical in most SPE applications (Figure 2). That’s where isolation transformers come in.

Chips vs. cases

Transformers are used in industrial SPE devices to meet the IEEE 802.3 standard and deliver 2,000 Vdc blocking. There are two transformer technologies to choose from, chip and case:

- Chip transformers are tempting since they are very compact. Unfortunately, most chip transformers can only provide a maximum isolation rating of 1,500 V and are unsuitable for industrial SPE isolation needs.

- Case transformers are wire wound on a ferrite core and can achieve up to 3,000 V or more isolation ratings. In addition, case transformers are available that combine the transformer and CMI functions, reducing component count and shrinking solution size. Finally, case transformers can be designed with a center-tap connection to ground that provides a low impedance path to ground for common mode signals.

Summary

SPE isolation inductors and transformers are required in emerging IIoT applications and machine and building automation applications. Simple capacitive isolation is insufficient at the higher voltages found in those applications. Transformer isolation is necessary to meet the requirements of IEC 62368-1. In addition, some SPE isolation transformers combine the functions of isolation and the CMI.

References

Single Pair Ethernet for Industrial Applications, Würth Elektronik

Single Pair Ethernet: How to implement 10Base-T1L, TDK

Transformer insulation advantage of Single-Pair-Ethernet, Magnetic Communication

What is a coupled inductor? Coilcraft