Testing and certification for vehicle and infrastructure devices ensure software and systems will perform as advertised.

Ralph Buckingham, Wayne Stewart, Intertek

As consumers look to connect their cars, the technology behind these vehicles and their various connected components is evolving far more quickly than standards governing them can change. Consequently,  manufacturers and developers sometimes lack clear standards or requirements when assessing vehicle subsystems and individual components. Instead, they are often on their own when it comes to testing. Fortunately, there are several rules of thumb, guiding principles, and certifications that can be used.

manufacturers and developers sometimes lack clear standards or requirements when assessing vehicle subsystems and individual components. Instead, they are often on their own when it comes to testing. Fortunately, there are several rules of thumb, guiding principles, and certifications that can be used.

Developers can evaluate systems and components via several methods and in a number of locations. Each offers its own benefits and drawbacks, so it is important to consider what will work best for the product or device in question. The following environments, or a combination of them, may be in order:

Laboratory testing: A lab allows for rigorous testing in a highly controlled environment. Here, engineers can evaluate products for safety, interoperability, functionality, connectivity, electromagnetic compatibility, overall performance, and controlled environmental exposure to elements such as UV, dust, water intrusion, and more.

On-road testing: Testing on the road brings real-world conditions (and often unexpected and random situations) like weather, geography, light, infrastructure, other vehicles, drivers’ actions and more. These tests can assess safety and performance over an extended period and provide a realistic view of a product’s lifespan and functions.

Proving-ground analysis: Testing on a proving ground acts as a combination of lab and on-road testing. It evaluates products in a real-world environment via a predictable, safe, and controlled setting. This method ensures specific elements are included in the evaluation such as direct sunlight, weather conditions, tunnels, on-ramps, and other potential obstacles. A proving ground can also allow testing to mimic real-world environments and applications, depending on the design and capability of the facility.

A thorough testing plan will integrate multiple environments and provide robust data as well as actionable results. For example, after initial proving ground testing, a product may be brought to a lab for an accelerated stress test to determine the breaking or weak points of the design (if any). Then, subsequent proving ground work can illustrate how the lab tests affected the product. All this information can be combined to identify pain points and mitigation efforts for product development, safety and performance.

Interoperability

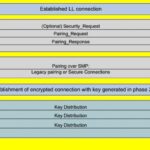

When connected systems interact with each other, it is important to ensure they exchange information without degrading performance or function. Interoperability assessments help guarantee these systems form an integrated ecosystem within the vehicle, communicating with one another seamlessly.

Testing cars and components for interoperability ensures they will work together without sacrificing performance. While the industry understands the need to ensure interoperability, today there is no standard to fully address it. So a common technique used in management systems has been adopted to assess connected device interoperability. It is a four-stage “Plan, Do, Check, Act” approach, providing an assessment methodology:

Plan: Identify improvement opportunities within a product and its systems. Use this information to identify and mitigate risk, develop an action plan, and address issues.

Do: At this stage, conduct evaluations and assessments, collect analytics and data, and document issues and failures. It is important to keep all the information on hand for future use, whether for a redesign of the current product or for future development.

Check: Review and analyze results from the previous stages, evaluate current processes and determine causes of failures. Use this information to determine whether interoperability goals are met or whether improvements and corrections have worked. As with other steps, documentation is important.

Act: Based on the previous observations and failures, implement changes. If problems persist, return to the “Plan” and “Do” phases until interoperability goals are met. Continue to reiterate the PDCA process until a product meets interoperability requirements.

One of the most effective ways to test for interoperability is to place products in a simulated environment and check for operational problems, as well as for how other devices in a system impact each other. On-road or proving ground testing help in assessing interoperability. Lab testing will also be important because software compatibility is a vital component of interoperability.

Cybersecurity

Like any connected product, cars and their components can have cybersecurity vulnerabilities. There are several ways manufacturers can mitigate cybersecurity risk in connected cars:

Develop and/or use certified products that are correctly configured. This tactic can help ensure products and components have undergone rigorous security evaluation against trusted industry standards. It will also aid in identifying security flaws early in development, reducing mitigation costs later.

Obtain certification of information security management systems. An information security management system can preserve the confidentiality, integrity and availability of information by applying a risk- management process to the design of processes, information systems, and controls.

Employ threat risk analysis and risk assessments (TARA), vulnerability assessments and penetration testing. Risk analysis and assessments can indicate weak points and establish fixes. Vulnerability assessments can identify latent vulnerabilities and recommendations for improvement. Pen testing illustrates how vulnerabilities can be exploited. All three can take place together or separately, depending on need.

Conduct supply chain assurance assessment and certification. One compromised link within a supply chain can affect many organizations. These checks can prevent maliciously tainted and counterfeit products from entering the supply chain.

Connected cars must interact with each other, the infrastructure, and other smart devices. It is important in this rapidly changing industry is to stay abreast of connected vehicle technology, threats, and consumer demands. As technology evolves, standards will begin to follow. Education and preparation help ensure the safety and performance of automated and connected vehicles.

Leave a Reply