Microcontrollers are designed to handle only low voltage and current signals on their input and outputs. So how does one control and drive a high wattage load such as an electric heater using an MCU? One of the easiest and most efficient ways is to use a Solid-State Relay (SSR). An SSR allows you to control high-current AC loads using low voltage DC control circuits while isolating the MCU from exposure to the output pin’s external load. MCUs can drive a very low current, low voltage signal from an output directly (e.g., LEDs). Such a low voltage signal is also enough to trip an SSR and engage the SSR’s contact (switch).

What are solid-state relays?

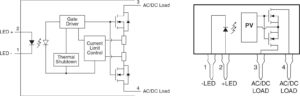

SSRs are semiconductor-based electronic switching devices that, when a low voltage signal is applied, will close a contact that can withstand high voltage and current requirements. SSRs are actuated using a small external DC voltage that’s applied across the SSR’s control terminals, and this is how small SSRs can control large electrical loads. In Figure 1, the IXYS CPC1511Y SSR’s inputs are pins 1 and 2, which energize an LED. The LED lights up, and the photo-sensitive receiver inside the SSR operates the Form A style contact/switch, which incorporates an effective circuit isolation from the MCU that’s directly driving the SSR’s input pins 1 and 2. Isolation is often a feature of SSRs, which benefits the MCU by protecting it from the load.

How SSRs work

Physically, SSRs have several integrated components that perform in stages:

- An internal sensor that responds to a control signal. Semiconductor switching elements such as thyristors, triacs, diodes, and transistors are used.

- A solid-state electronic switching device switches power to the load circuitry.

- A coupling mechanism without mechanical parts. Optical semiconductors (photocouplers) are used to isolate input and output signals by changing electric signals into optical signals, which isolates the input and output sections while relaying the signals at high speed.

SSRs have several advantages over electromechanical relays (a prior technology). SSRs can be operated using a lower voltage as the control signal than electromechanical relays. SSRs can switch much more swiftly, and for longer periods without wearing out. SSRs don’t make any noise, working in silence. You can hear electromechanical relays as they engage. SSRs create no arcs or sparks, which is critical for explosive or high-oxygen environments like operating rooms, and they are much less sensitive to environmental factors like mechanical shock, vibration, and humidity. Electro-mechanical relays are still useful for very high amperages since SSRs with high current ratings (~150 amps and higher) are expensive due to the need for power semiconductor electronics and heat-sinks. On the other side, one can see and hear an electromechanical relay, which can be convenient for troubleshooting. However, the possibility for features in SSRs can be many, such as the CPC1511 from IXYS, which includes “built-in current-limiting protection circuitry, thermal shutdown, linear AC/DC operation, low power consumption, clean, bounce-free switching, and an extended operational lifetime over electromechanical relays.”[i]

How to choose a solid-state relay

When choosing an SSR, first determine whether you need to switch an AC or DC load. Next, determine the maximum voltage level that you will be switching, potentially planning for in-rush current, as this is what determines the rating of the contacts. If you are switching DC from batteries, assume your voltage is at least 25% more than your battery’s rating. If you are switching AC (line) voltage from a wall socket, use the local electrical grid standard as your voltage. Next, determine the Average Load Current (ALC), which is simply the wattage of your load divided by the operating voltage. You also need to know the inrush current drawn by your load (e.g., some might size an overload protection device at no greater than 125 percent of the nameplate current rating on a load that’s a motor). You can calculate inrush (or surge) current in many ways by estimating or accurately with tools like oscilloscopes or a clamp meter with inrush measurement capability. The

SSRs must be kept cool for reliability and long life. One rule of thumb is to keep the metal base of the SSR at less than 85°C (185°F). Excess heat can be an indication of too much current, need for a heatsink, or by frequently turning the relay on and off. You can use a thermocouple to measure the temperature of the metal base, especially if the SSR does not have its own thermal shutdown circuitry.

[i] “Press Release – Ixysic.” IXYS Integrated Circuits. N.p., n.d. Web. 17 Oct. 2017

Hi

can 700 watt inverter with dc to ac ssr relay 150 amps power a 6000 watt heater