Basic Single-Pair Ethernet (SPE) requires at least a common mode inductor (CMI). When power over data line (PoDL) functionality is added, so is a differential mode inductor (DMI) and sometimes an isolation transformer. These magnetic elements interact and can reduce SPE performance. Correctly specifying them is important to ensure efficient operation and reliable data transfer.

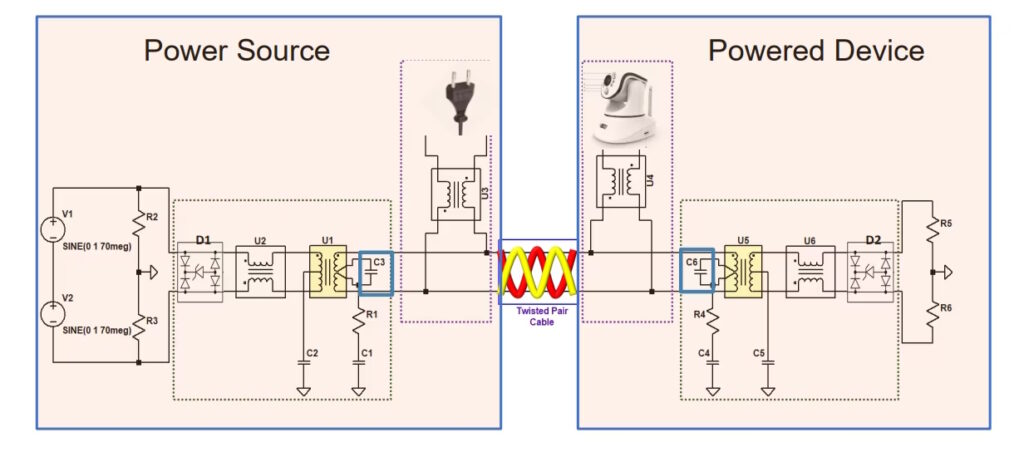

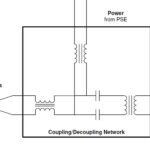

PoDL is designed for point-to-point power delivery and does not support multidrop power delivery. The PoDL system consists of the power sourcing equipment (PSE) and the powered device (PD) (Figure 1). IEEE 802.3bu defines 4 types of PSEs, including ten classes rated for 12, 24, and 48 Vdc unregulated and regulated power delivery. IEEE 802.3cg added a new PSE type and added 30 V and 58 V classes, bringing the total to 16 classes. Optimized coupling of the power onto the data channel is important, PoDL can affect the channel through the coupling network in several ways:

- Mode conversion and return loss can be affected by the DMI and its interaction with the transformer.

- Power supply noise, dv/dt, and di/dt can reduce data integrity.

The coupling-decoupling network (CDN) that connects the SPE electronics to the cabling uses the CMI (U2 and U6 in Figure 1) to reduce common mode interference on the differential signals. The CMI can be placed before or after the coupling circuit. If the CMI is after the coupling circuit, the power current flows through it, and the CMI can be used to improve the symmetry of the power injection. If the CMI is before the coupling circuit, the power current does not flow through it, and the same CMI can be used for PoDL and non-PoDL applications.

The transformer (U1 and U5 in Figure 1) provides isolation for safety-critical applications, and the isolation rating is application dependent. The DMI (U3 and U4 in Figure 1) must have a saturation current as defined for the power class being deployed (there are 16 power classes). The inductance of the isolation transformer is parallel to the inductance of the DMI. Clause 104 requires that the total inductance must be high enough to minimize loading at frequencies of 7.5 MHz or higher and specifies a maximum 25% signal droop.

In addition, the higher current defined for the highest power class, class 15, requires a different architecture. In this case, a line-side injection can be used, and the DMI can be placed between the CMI and the connector. The CMI can be smaller since it does not have to handle the power being transmitted only the data signals.

SMD DMIs

Specially optimized DMIs are available for PoDL applications. One DMI product family includes devices that cover power classes 10 to 15 for industrial applications as defined in 802.3cg. They feature saturation currents from 360 to 2,100 mA and are designed for operation from -40 to +125 °C. Another option is a part designed for use in class 15 power applications as a single inductor for noise suppression and smoothing of currents with a saturation current of 2,300 mA. (Figure 2).

Summary

SPE requires a CMI. When PoDL is implemented, it also requires a DMI and an isolation transformer. Potential interactions between these magnetic components can reduce system performance and demands careful attention when they are being specified to achieve reliable data transfers and power efficiency.

References

A Quick Walk Around the Block with PoDL, IEEE

How to Implement an IEEE 802.3cg or 802.3bu-Compliant PoDL PSE, Texas Instruments

Power over Data Line is ready to use, Renesas

Leave a Reply