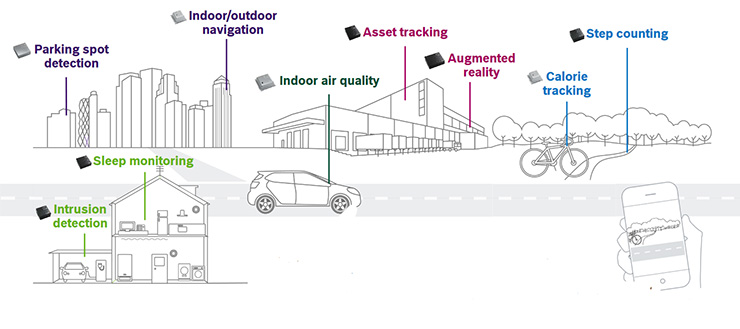

Part 2 of this series continues with answering common questions about how sensors work in IoT system development.

What are smart sensors?

Basic sensors can detect changes in their environments and convert measured data into a digital format for the external microcontroller to process. The “smart” is in the microcontroller. Combining the microcontrollers in a single package makes it possible for the sensors to become “smart.” Modern technology enables this combination to be accomplished within small packaging.

For example, Bosch Sensortec’s BHA250 can integrate a 32-bit microcontroller with a 14-bit acceleration sensor in a 2.2 x 2.2 x 0.95 mm3 package. Another sensor manufacturer, TE, for instance, has integrated sensors with connectors to pack functionality into a small space.

Q. How difficult is it to do system design with sensors?

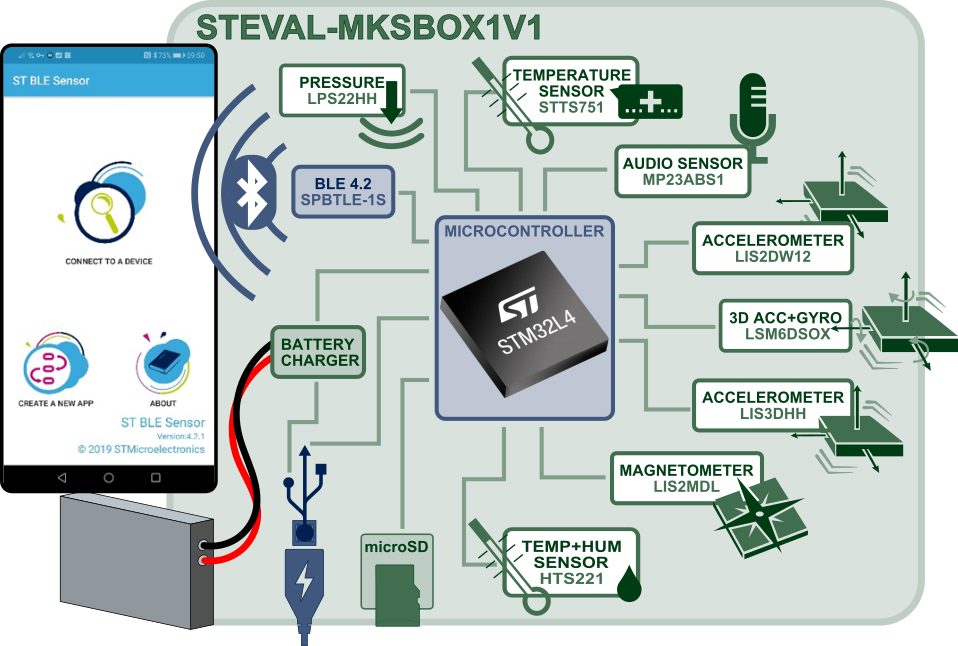

A. Sensors and silicon manufacturers assist developers with ready-to-go developer’s kits to make design work easier. Developers can use the kits to do proof of concept before doing the final design. Here is an example.

STMicroelectronics recently introduced a flexible unit called the SensorTile.box. A functions board, including a low-power Arm Cortex-M4 microcontroller with DSP and floating‐point unit (FPU) and multiple sensors, is packed in a small box (57 x 38 x 20 mm3 ) (Figures 3 and 4). Bluetooth functions are built-in. For developers desiring quick results, the kit does not require programming. But it also has an Expert Mode for developers to do custom programming. Furthermore, the STMicro STM32 Open Development Environment (STM32 ODE) supports more complex programming with AI and neural network libraries. More and more smart and integrated solutions are becoming available from various vendors. It pays to explore.

- Digital temperature sensor

- 6-axis inertial measurement unit

- 3-axis accelerometers

- 3-axis magnetometer

- Altimeter/pressure sensor

- Microphone/audio sensor

- Humidity sensor

Q. What are the considerations in choosing a sensor solution?

A. A few criteria should be considered when selecting a sensor solution:

- Accuracy in terms of precision and resolution. Determine in advance what resolution you need. In the case of temperature, will accuracy within 1 degree be accurate enough? For distance, you may need accuracy as low as units of 0.01 inch. The higher the resolution, the higher the cost.

- Measurement range. What is the upper and lower limit you need? If you don’t need a wide range, it will reduce your design cost.

- Environmental conditions. Does it have to perform in high temperature/humidity conditions or be waterproof?

- Reliability considerations. There are two aspects. One is how long the sensors will function without breaking down. The mean-time-between-failure (MTBF) specification refers to the length of time that sensors can function without experiencing failure or breakdown. This will be important for sensors operating in remote and rugged areas. The other aspect is whether the sensor’s performance is accurate without calibration. It is possible to have sensors that have not broken down but require calibration to perform accurately.

- Rugged environment. Some sensors must withstand extreme heat, cold, shock, and vibration. Make sure the sensor you select will meet the requirements.

- Size and weight requirements. Depending on the applications, some sensors must fit in very small spaces, or many sensors need to be installed for one application.

- Tradeoffs—highly integrated solution vs. using individual components. An integrated solution may cost a bit more, but can ave design and installation time. For example, a vibration sensor with a built-in LoRaWAN or RF communication function will take up less space and installation time.

- If the applications are critical and require redundancy, consider sensors with a dual-package.

- Overall system cost. Finally, take a look at the overall design, install, and support costs and not only the sensor’s individual unit cost.

Leave a Reply