This is the first in a three-part tutorial series explaining how to implement the product development cycle process.

Nearly everyone knows Microsoft Excel. Fewer know Lotus 123, and almost no one remembers VisiCalc, the first version of a spreadsheet computer program for personal computers, which ran on the Apple II. There have been a few one-time wonders, including AOL, the first email, and the first word processor (invented by Wang Computer).

Successful product innovations require a sustainable product development cycle management process, supported by an environment of innovation. In this article, we’ll explain how the process works for embedded system developers. The key to success is combining an understanding of the product development cycle (PDC) management with successful implementation.

Here we provide an overview of the product life cycle (PLC) and product development cycle (PDC) and an explanation of the difference between the two. Part 2 explains in detail the 12 steps of PDC, and the final part provides some practical suggestions on PDC implementation.

Product Development Cycle (PDC) Management overview

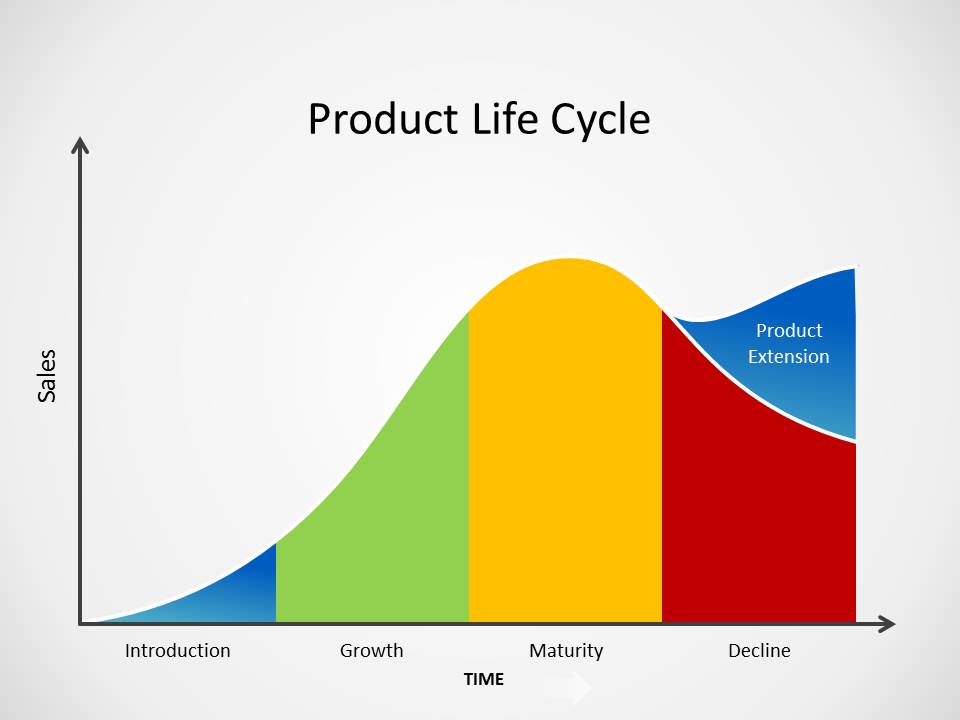

The Product Development Cycle (PDC) is different than the Product Life Cycle (PLC). Let’s first examine the product life cycle. A typical product goes through four PLC stages, as shown in Figure 1:

- introduction

- growth

- maturity

- decline

A product has to be developed first. After it is ready, it will be introduced to the market to be sold. This is the beginning of a PLC. Then it would grow and flatten out before declining.

In some cases, a product extension plan will be implemented to extend the life of a product. It is important, therefore, to have a new replacement product ready before a product starts to decline. Some refer to this cycle from introduction to obsolescence as “from cradle to grave.”

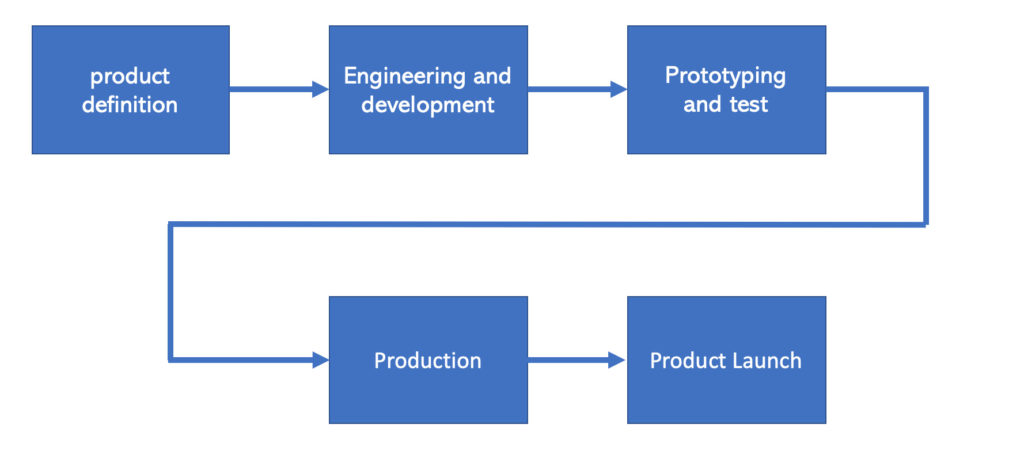

Now, let’s look at the Product Development Cycle (PDC), which differs from the PLC. A PDC comprises the activities and efforts taking place to ready the product for the introduction or launch. Many start-ups are founded by brilliant engineers with great product ideas and enthusiasm. Without knowing the complete cycle, many entrepreneurs find themselves in frustration when running into hurdles during the product development cycle. Other founders have wasted valuable resources due to lack of knowledge. Since PDC can be a complicated process, it would be beneficial first to understand its simplest form, a simple five-step version.

As shown in Figure 2, a PDC at a high level has five stages: (1) product definition, (2) engineering and development, (3) prototyping and test, (4) production, and (5) introduction (launch). Most founders with a strong technical background are good at stages one and two. However, in a rush to introduce a new product, the test cycle planning is sometimes not so thorough. As a result, customers who have agreed to be a beta test site (more details later), often complain because they have to keep trying out different versions of the products. Additionally, some technical founders spent all their time in engineering, often forget about how much time it would take to do production planning and marketing.

For example, many contract manufacturers use standard production equipment. Often time, knowing ahead of time the standard width of the assembly tray will allow more printed circuit boards to be squeezed together to reduce material costs. This would also increase production efficiency as one production run will be able to produce more products.

In Part 2, we will explain in detail the 12 steps of the product development cycle (PDC).

Leave a Reply