The article Why Clean PCBs Matter, Part 1, covers the effects that a dirty Printed Circuit Board can have on electronics, especially those supporting high-frequency signals or sensitive analog components. Keeping a PCB clean begins in assembly when components are preferably soldered to the PCB in a clean environment. Of great importance is the type of flux used and whether you clean residues off the PCB.

Residues remain after PCB assembly

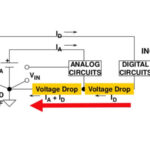

Depending on what you use to clean boards, after a PCB is soldered, flux residue can still be left behind. Chemically activated rosin-based fluxes contain bromides or chlorides which promote corrosion and affect the overall performance of circuits.[i] To ensure long-term reliability and durability of a circuit, you must clean flux residue thoroughly from the PCB. If possible, use no-clean flux. Non-conductive, no-clean fluxes still leave a little residue. However, no-clean flux evaporates, or outgasses in a heated environment, leaving barely any harmful residue behind.

Nevertheless, the minimal residue that is left by no-clean flux can be tough to remove and still provide a conductive path for sensitive circuits, such as high impedance analog circuits, so use with caution or review your choices thoroughly beforehand. Cleaning a PCB of flux residue can also cause the residue to migrate all over the board if the solvent that you use isn’t the right one. An ineffective solvent can smear the residue all over the PCB, making the residue problem worse.

Pollution-free storage and operating environment

If you have a PCB that you do not plan to use for a while, seal it in a box or bag to keep contaminants out. Unless you make your PCB connections using a material like gold, even a clean but humid environment can affect the durability of a solder joint, since many metals are prone to oxidizing (forming a film like rust) upon exposure to humidity at high temperature. If a PCB must operate in a non-ideal environment, then you should check on the PCB every few years as a best practice and remove dust build-up or other contaminants. The period between checking up on the PCB to remove dust, hairballs, cola spray, and other disgusting deposits depends upon the level of pollutants in the environment and the protective ability of the PCB’s case.

How to clean an assembled PCB

PCB cleaning is a careful process because it’s easy to mishandle a PCB in such a way that it can permanently damage an integrated chip (IC). Do not clean a PCB if it is operating properly and does not seem considerably dirty. Some chips have integrated temperature sensors that can help to warn you of a PCB that has a build-up of dust, hair, or fluff that acts as an insulator.

There are multiple levels to clean a PCB. Choose a procedure according to the PCB’s condition.

Removing dirt and dust

With dry pollutants such as dirt and dust, you can easily clean a PCB can with the help of a soft, clean, dry toothbrush. Toothbrush bristles are flexible and can whisk away pollutants from narrow spaces. But make sure the toothbrush is not rubbed with excessive force as the solder joints can be damaged upon mechanical stress. Use some isopropyl alcohol if wetting the toothbrush might help. And although it goes without saying, make sure to remove power before proceeding.

Compressed air is good for cleaning PCBs but never use a vacuum cleaner unless there are no ICs and you know what you are doing. An operating vacuum cleaner can create an electrostatic discharge on the hose which can permanently damage components on the PCB.[ii]

Removing grime

Removing grime is not as easy as removing dirt. Grime forms when oily substances gather dust. To remove a spot of grime, try using rubbing alcohol on your toothbrush. Otherwise, to remove grime, you may need to remove sensitive components from the PCB so you can immerse the PCB to clean it. Removing components can damage them, however, so it’s best to clean parts individually, avoiding water on devices that are not encapsulated or can’t take water without breaking. Desolder components after noting their position so you can solder them back on again after cleaning.

Phosphate-free detergents can remove grime from a PCB. Dip an IC-free PCB in a detergent bath for approximately ten seconds and then brush it with a toothbrush. (Remove any other components that are not water-proof or robust enough to stand up to a bath.) After you have removed the grime, clean the PCB with a lint-free cloth and let it dry completely, then solder all components back to their positions.

Removing flux residue

Removing flux residue can be challenging as compared to dust. Many people use anhydrous alcohol for cleaning PCBs. One option for cleaning a PCB is to wet a toothbrush scrub the PCB thoroughly.

Neutralizing and removing corrosion

Solvents like battery acid can cause severe damage to a PCB if you do not neutralize it as fast as possible. Apply a thin mixture of water and baking soda to the acid-affected area to neutralize it first. Wearing gloves is a good idea.

Note that not all batteries are alike. NiCad batteries contain bases, and therefore cannot be neutralized with a water-baking soda solution. With base-related spills, you can use white vinegar as a neutralizing agent. After neutralizing the acid, soak your PCB with a non-fiber, lint-free cloth and follow the above grime removal procedure for thorough cleaning.

PCB storage

Ideally, store a PCB in a pollution-free environment. It’s nearly impossible to keep a PCB in an environment that is entirely free from dirt, dust, grime, flux-residue, humidity, acids, or other pollutants. However, you can protect a PCB to some extent in a couple of ways.

Even if your PCB is unassembled, store it in a bubble-wrapped vacuum bag with silica gel to protect against possible moisture and air exposure. Keep the package in a robust casing for better protection. Keep it stored whether or not you have populated it with components yet until you are ready to use it.

For better protection, consider applying a conformal coating, which can protect a PCB from adverse environmental conditions such as moisture, temperature, and pollution. A conformal coating is sprayed on so that a layer completely covers the circuitry, reducing chances of exposure to chemicals or pollutants.[iii]

PCBs are efficient and durable as long as you maintain and protect them against pollutants. It is essential to check PCBs occasionally and clean them if necessary before pollutants can cause problems that lead to break down and require troubleshooting.

References

[i] https://www.ipc.org/TM/2.3.28.1.pdf

[ii] https://wiki.arcadeotaku.com/w/PCB_Cleaning_101

[iii] https://en.wikipedia.org/wiki/Conformal_coating

That’s good to know that you will have to be quite careful when cleaning the boards. I could see how they would have such little and intricate parts, that accidentally using too much force could easily damage them. I’ll make sure to be as careful as possible if I ever have to clean a PCB.